Contact Us

- 18 Yangdong Road, Xinzhuang Town, Changshu, Suzhou City, Jiangsu Province

- sz_shf@126.com

- +86-512-66836175

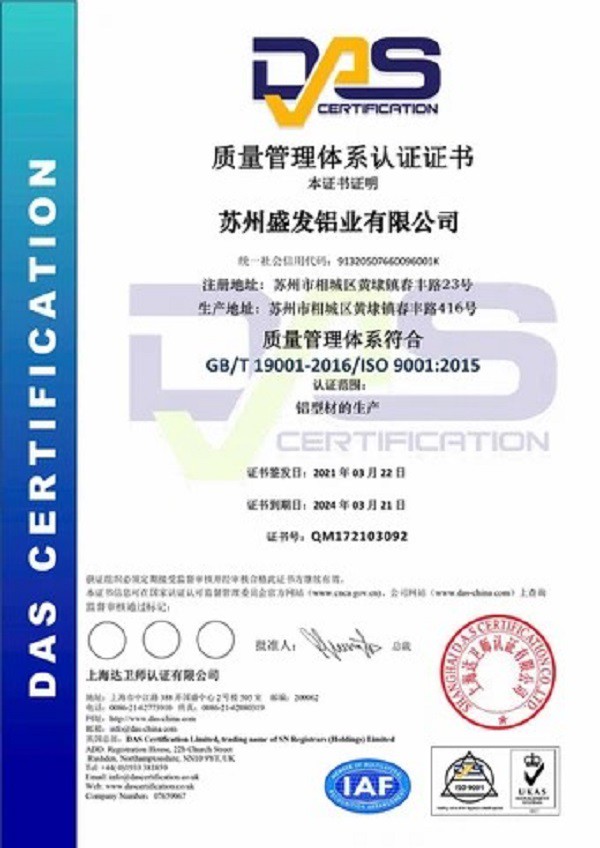

Founded in April,2007, Suzhou Shengfa Aluminium Industry Co.,Ltd has been a leading aluminum extrusion, machining and surface treatment manufacturer in China with fine quality, prompt customer service and overall solutions for customer products. Shengfa acquired Jiangsu Province Quality and Integrity Double Guarantee Demonstration Unit in Nov.,2011, acquired Jiangsu Province Intergity Management Demonstration Unit in Mar., 2015, acquired Jiangsu Province Private Technology Enterprise in Oct.,2019, acquired ISO9001 International Quality System Certification in May, 2015, acquired IATF 16949 International Quality Systerm Certification in Jul.,2021.

Toolbox Handle

Toolbox HandleWelcome to Shengfa! We find solutions, where others surrender. With a large range of products and an all-around service from the inquiry to the delivery and beyond.

Add to Inquiry Miter Saw Aluminium Cutter Table and Supports

Miter Saw Aluminium Cutter Table and SupportsLight weight and large loading capacity can provide convenient transportation and usage.

Add to Inquiry

Why Choose Us

Production Equipment

Shengfa has more than 3,000 dies, 630MT, 830MT, 1250MT,1600MT, total 4 extrusion lines, 2 sets of sandblasting machines, 6 sets of plane sawing machines, 3 sets of double end sawing machines, 1 set of 4.5m CNC machine, 2 sets of 850mm CNC machines, 8 sets of punching machines, 2 sets of tapping machines and 1 oxidation line.

Rich Experience

Shengfa covers an area of 5,000m2, have 15 years experience in aluminium extrusion profiles, with 8000MT annual production capacity, can provide aluminium extrusion profiles, semi-finished components, semi-finished systems and finished products.

Product Market

Shengfa is raw material supplier of heatsink for American NEV in China, raw material supplier of on-off control for germany brand, exported to Japan, Malaysia and other Southeast Asian countries.

OEM / ODM Services

Shengfa provides OEM and ODM services according to DIN EN, ASTM, GB/T standards and customer requirements.

The Electric Tool Parts Our Company Provides Include the Following Products

Specification

|

Material Grade |

Aluminium alloy 6005,6060,6063 |

|

Temper |

T5,T6 |

|

Thickness |

General profiles thickness: 0.7 - 10.0 mm; Anodized protection thickness: 8 - 25 um; Powder coating color thickness: 40 - 120 um. |

|

Surface Treatment |

Bright anodizing,silver anodizing,black anodizing,powder coating,sandblasting anodizing, Alkali sand anodizing |

|

Color |

Metal silver, champagne, black, white, mirror, customized request available |

|

Deep Machining |

CNC, drilling, milling, cutting, welding, bending, assembling, punching, etc. |

|

MOQ |

Order from 300kg for small profiles and 500kg for large profiles |

|

Production Capacity |

800 tons monthly |

|

Certificate and Standard |

ISO 9001,IATF16949 quality management certificate |

Advantages of Toolbox Handle

Comfort and Durability

The handle is designed with ergonomics in mind to provide a good grip and comfort and reduce fatigue during prolonged use. For example, the handle of Mijia Toolbox has a thicker and wider design, which increases the force area and makes it more comfortable to hold and carry. The surface of the handle is usually treated with a non-slip texture, which ensures a firm grip and prevents slipping even in wet or oily environments.

Aesthetics and Practicality

The design of handles focuses not only on functionality but also on aesthetics. For example, ESCO XIYI lightweight handles are made from high quality aluminium alloy, precision machined and heat treated to ensure excellent strength and corrosion resistance while maintaining a very low weight, improving the overall life of the tool.

Ergonomic design

Many handles are designed with ergonomic curves to fit the contours of the hand, providing just the right amount of support and wrap to reduce hand fatigue. For example, the unique design of the ESCO Hi-One lightweight handle fits perfectly in the palm, fingers and wrist, keeping the hand comfortable even during long, intensive use.

Shock absorbing and Non-slip design

The end of the handle is usually equipped with a soft rubber cushion, which not only increases the stability of the handle, but also has a good shock-absorbing effect, improving handling precision and safety. For example, the soft rubber cushions at the end of the ESCO XIYI lightwei

Applications Areas of Toolbox Handle

Industrial field

In factory production line and mechanical equipment, tool box handle is often used to operate various tools and equipment, to improve work efficiency and reduce operator's physical exertion.

Automobile maintenance

In automobile maintenance, tool box handle is widely used for various maintenance tools, such as angle adjustable wrench, this design makes the operation more flexible and convenient.

Home maintenance

Home toolbox handle set contains a variety of tools, suitable for home maintenance scenarios, such as faucet repair, home improvement measurements and electrical repair, etc.. These tools are well designed and easy to carry. These tools are well designed and easy to carry, which can meet the daily home maintenance needs.

Outdoor activities

In outdoor activities, such as camping, hiking, etc., the tool box handle is used to carry and operate a variety of outdoor tools, such as multifunctional hand drills, electric screwdrivers, etc., providing a convenient operating experience.

Advantages of Miter Saw Aluminium Cutter Table and Supports

Lightweight

Aluminum alloy bracket has lightweight characteristics, easy to transport and install, reducing labor intensity during installation.

Corrosion resistance

Aluminum alloy has good antioxidant performance, not easy to rust, suitable for humid or corrosive environment.

Aesthetic

Aluminum alloy bracket has smooth surface and beautiful appearance, which is suitable for occasions with high aesthetic requirements.

Stability

Aluminum alloy bracket has a solid design, which can ensure the stability of use.

Heat Dissipation

Aluminum alloy has good thermal conductivity, which helps to dissipate heat.

Environmental protection

Aluminum alloy is a recyclable material, which meets the requirements of environmental protection.

Applications Areas of Miter Saw Aluminium Cutter Table and Supports

Construction field

Aluminum alloy brackets are widely used in the construction field to support and fix various structures, such as scaffolding and formwork support. Its light weight and corrosion resistance make it perform well in wet environment.

Industrial field

In factories and warehouses, aluminum alloy supports are used for storing and transporting goods, and their strong, durable and easy-to-clean features make maintenance work easier.

Home decoration

Aluminum alloy bracket is also widely used in home decoration, such as book shelves, display shelves and so on. Its beautiful and easy-to-clean features make it an ideal choice for modern home decoration.

Our Services

In sales, we will follow up production and inform customers of progress

Pre-sale

We can design and render drawings, offer suggestions according to customers’ requirements

After sales

We will help customers arrange delivery, make documents for customers.

Our Certificate

Supply Ability

The company conducted a competitive advantage analysis to identify its strengths and weaknesses compared to its rivals.

Raw material

6063 aluminum alloy

MOQ

500kg

Color

Black/Silver/Custom

Payment method

Telegraphic transfer or letter of credit

Delivery terms

Negotiable

FAQ

As one of the most professional electric tool parts manufacturers in China, we're featured by quality products and low price. If you're going to buy cheap electric tool parts for sale, welcome to get quotation and free sample from our factory. Also, customized service is available.

Electric Tool Parts, Miter Saw Aluminium Cutter Table and Supports, Toolbox Handle